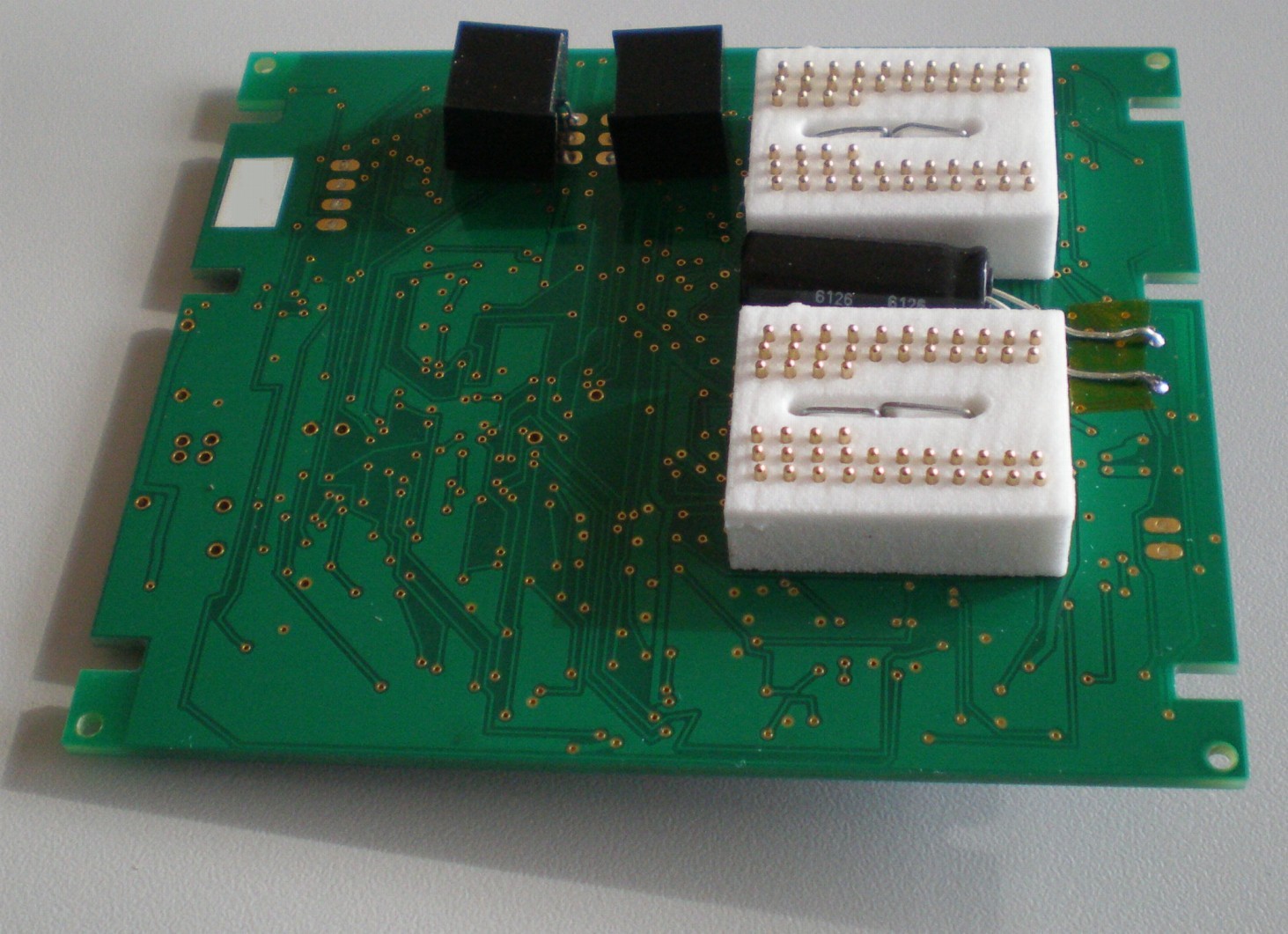

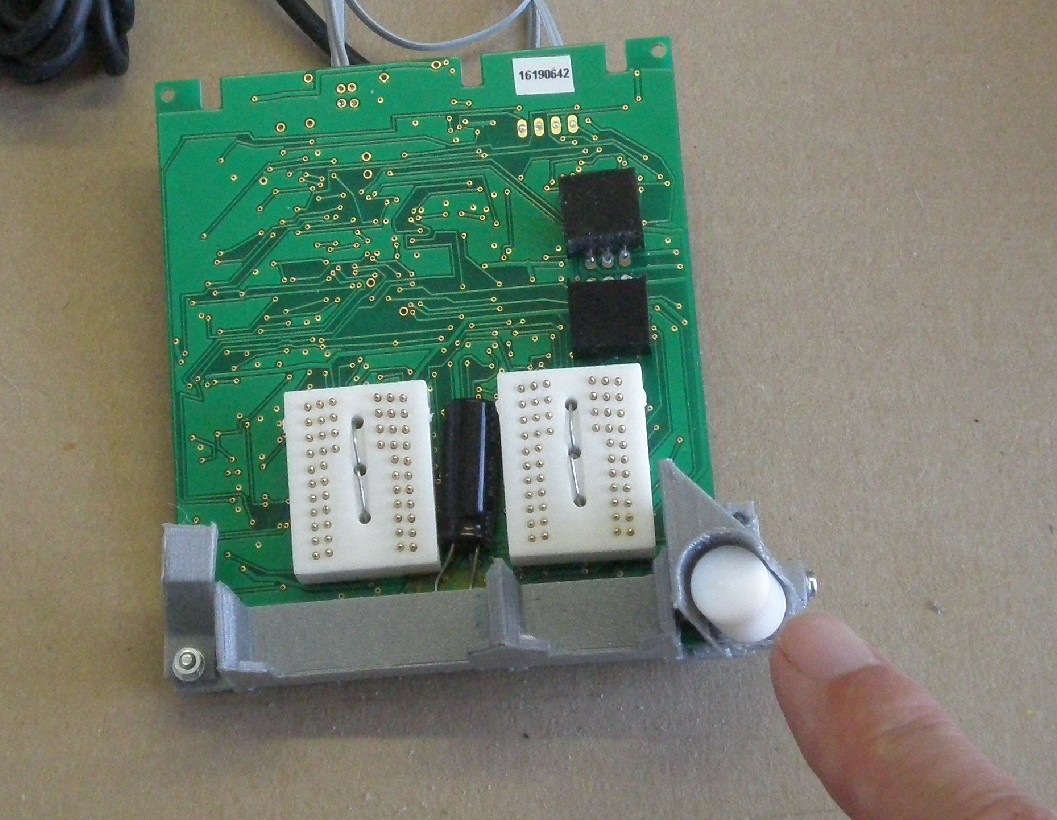

The colorpod backside with gold plated contacts to connect to the inkjet cartridges

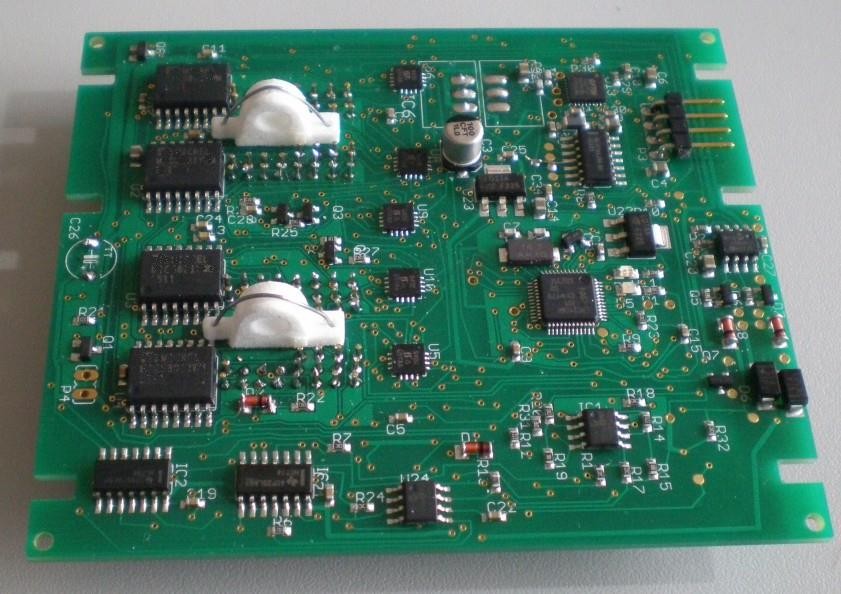

The front side where the electronic components are

The addon set with 200 grams of pva powder and inkjet cartridge filled with colorless fluid

and all the nuts and bolts you need. The ColorPod and add on set are avaialble at this webshop

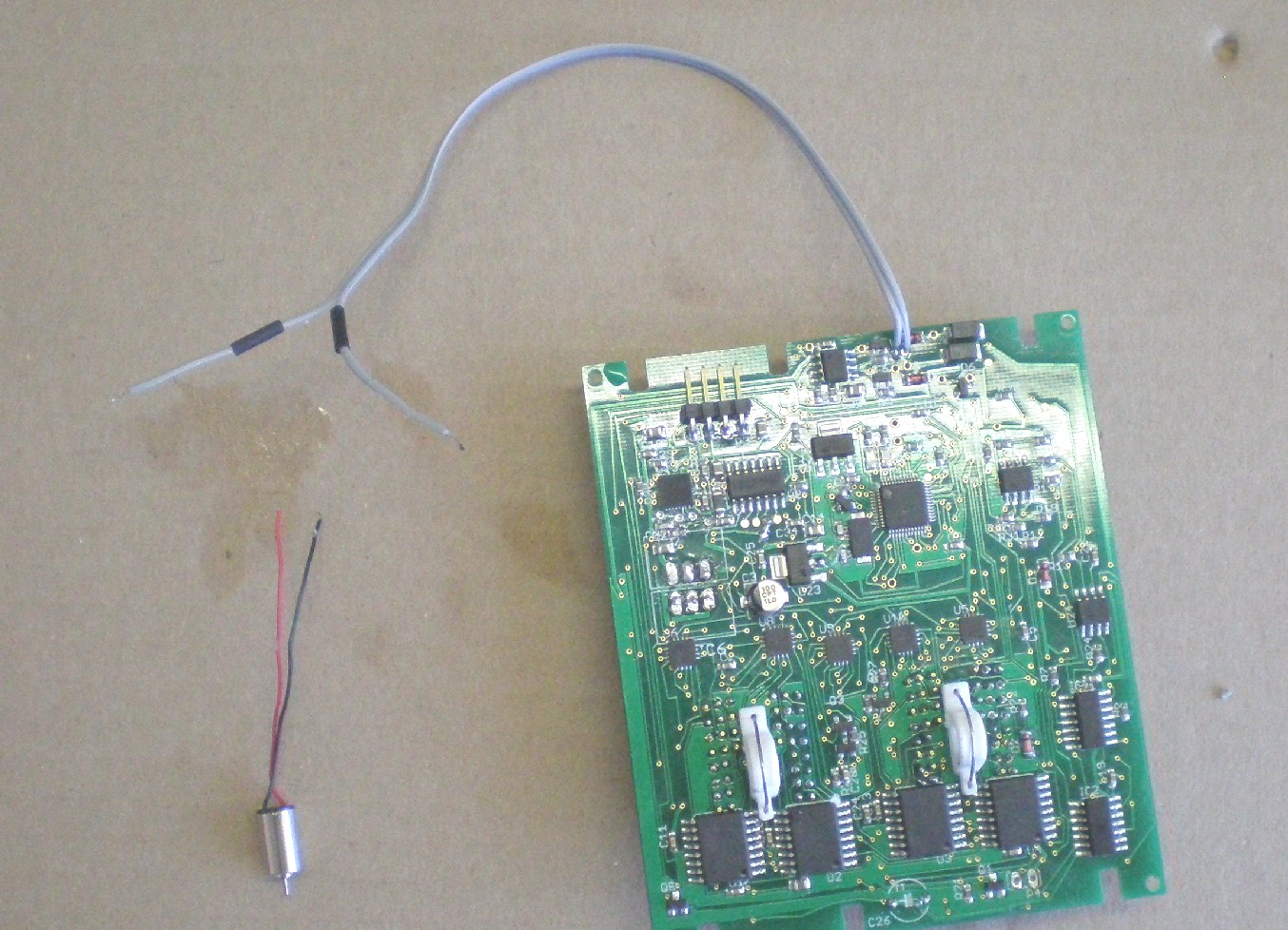

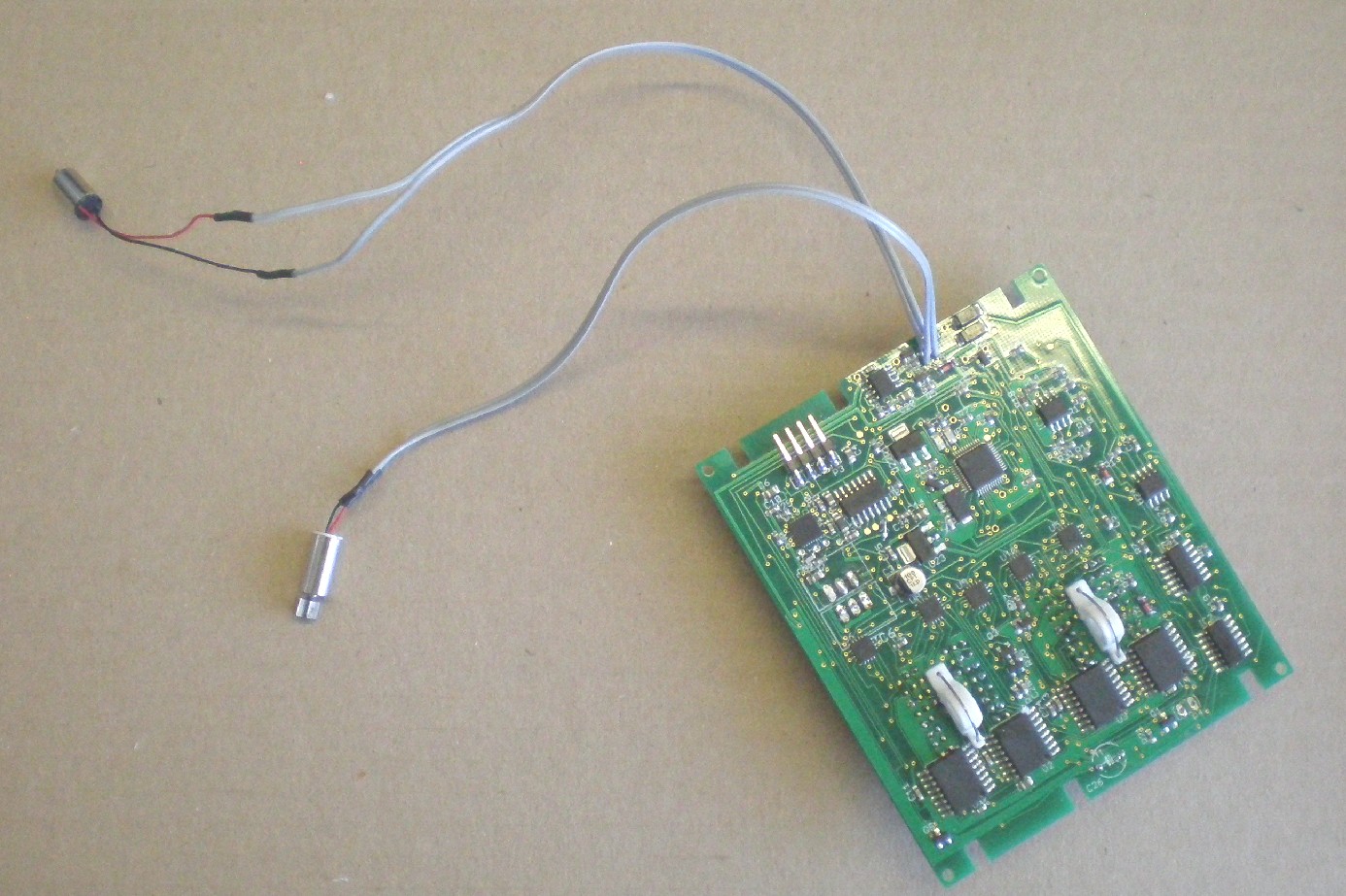

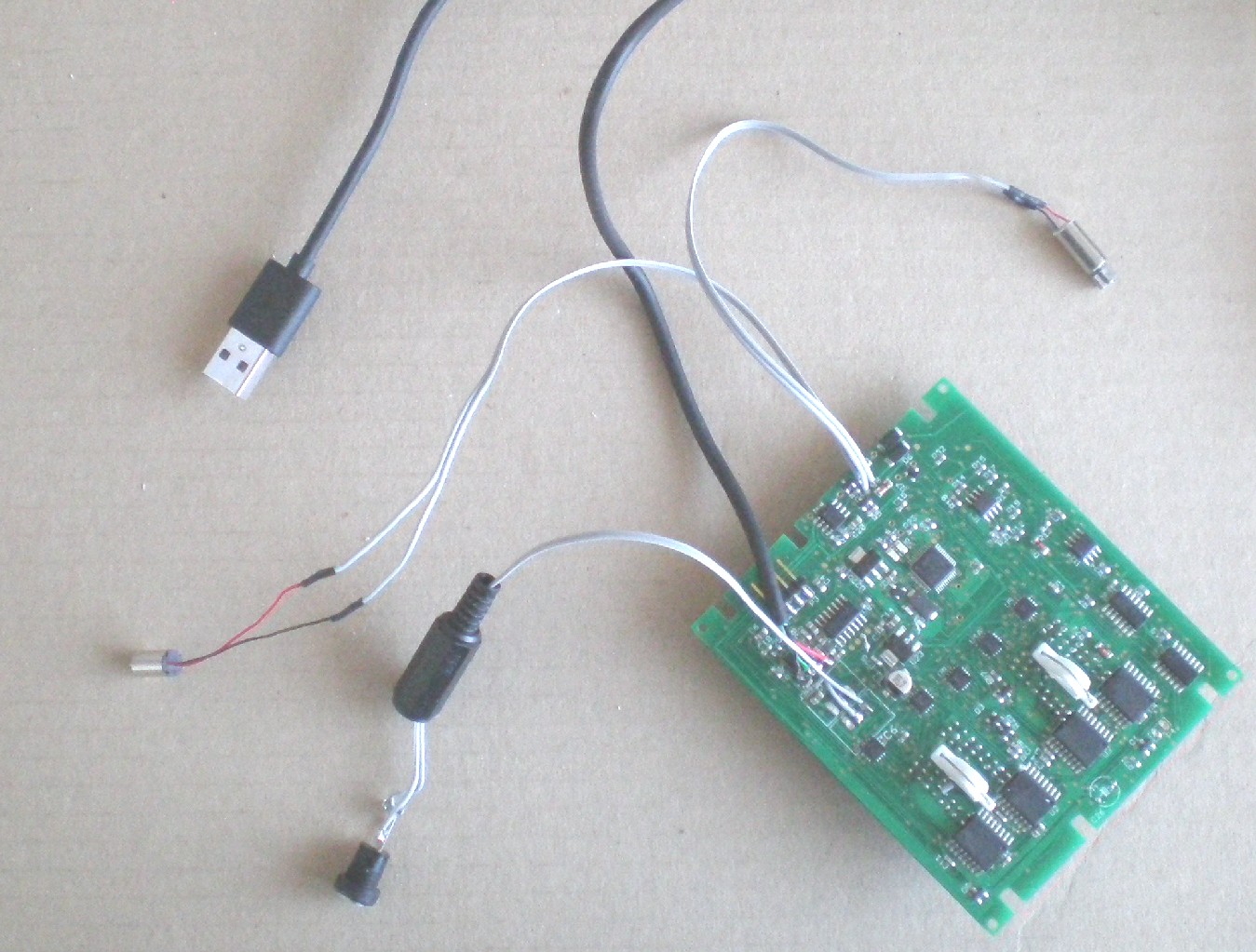

These are the electrical connections you need to make for the ColorPod to work. It works from a 12V supply (minimal 1.5A). You need to connect an USB cable and two motors. The vibration motor is for sprinkling of powder. The roller motor is for the levelling of the powder layers.

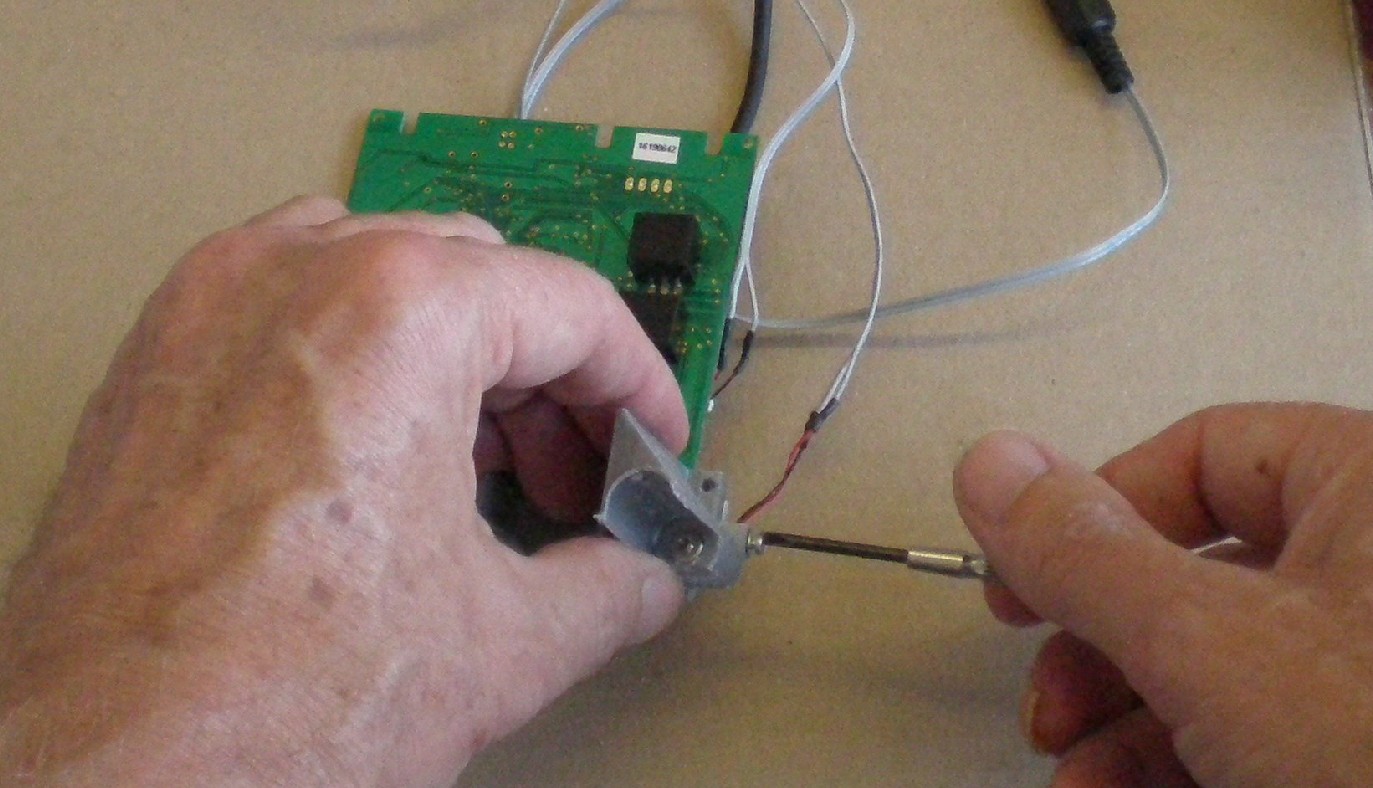

The motor wires may not stick out of the other side of the pcb. It is best to strip them very shortly (1.5mm) .

Before you solder the motor slide some heat shrink tubes on the wires. The blue wire must be connected to the right pad on the pcb. The red to the left pad.

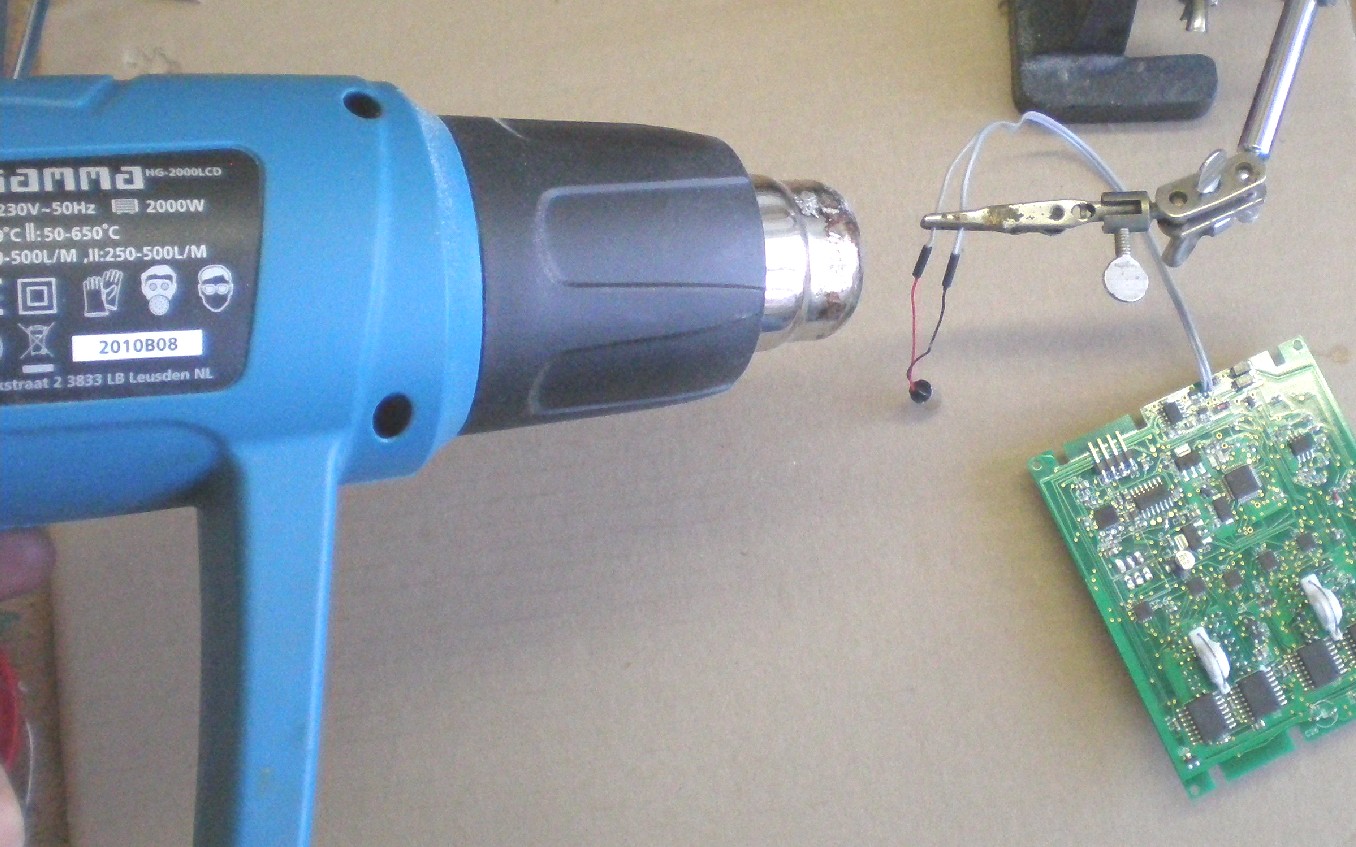

Let the tubes shrink by applying heat with a heat gun. You can also use cigarette lighter.

Connect the vibration motor in the same way. Polarity of this motor is not relevant.

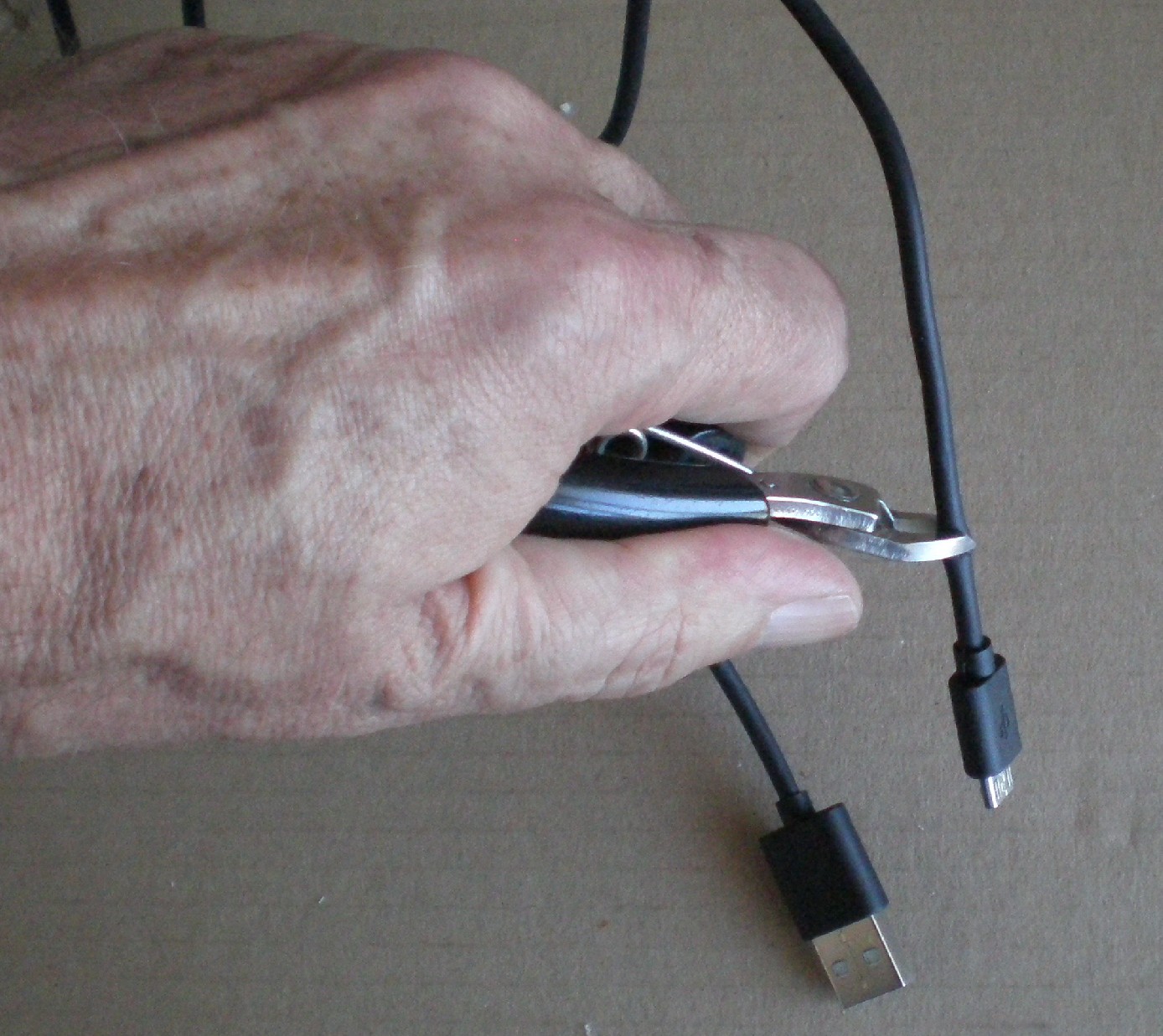

You need an usb cable. You can cut of one side and strip the wires.

Solder the usb cable to the pcb. It is best to check the color coding of the wires with a ohm meter.

Solder the power plug with wires on the pcb.

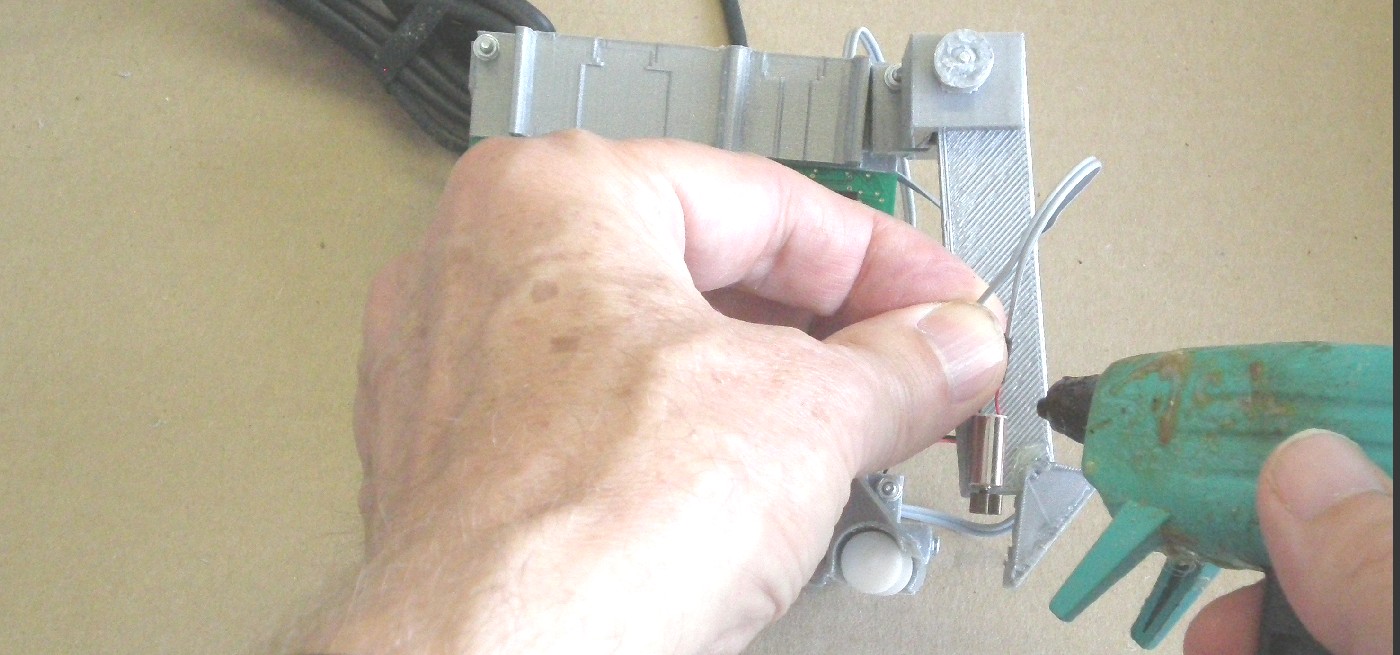

secure the soldered connections on the pcb wit a glue gun

It is best to also secure the connections in the power plug

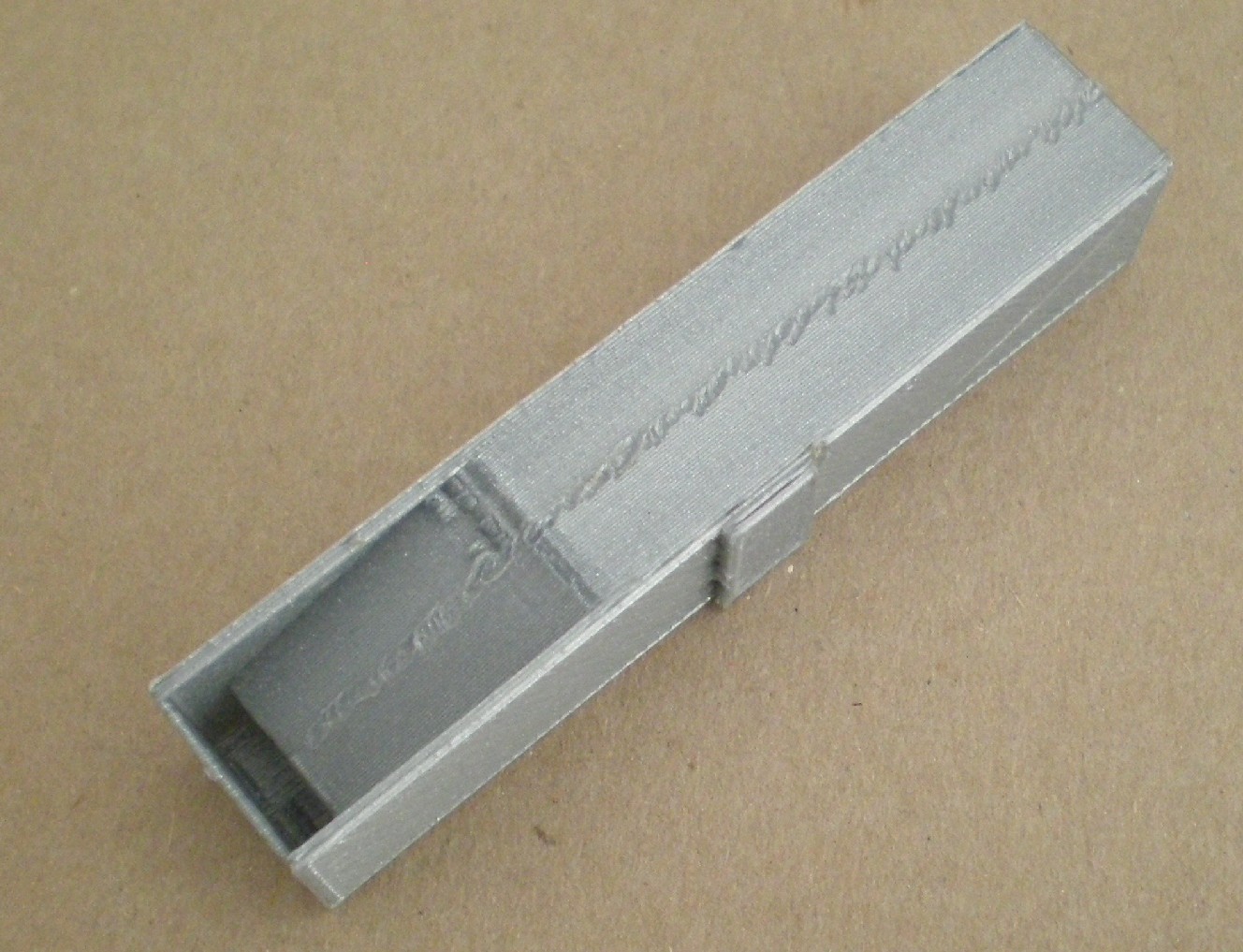

These are most of the parts that need to be 3d printed. They are made from PLA. The funnel and the parts that operate the endstops are not on this picture. This set is for printing with an ultimaker 2 or 2+.

you can download stl and step files here

The 3 parts of the powder sprinkler can be melted together with a soldering iron or glued with glue.

The square holes in the sprinkler are for a sensor that controls the feeder unit. It is recommended that you first test without sensor and without feeder

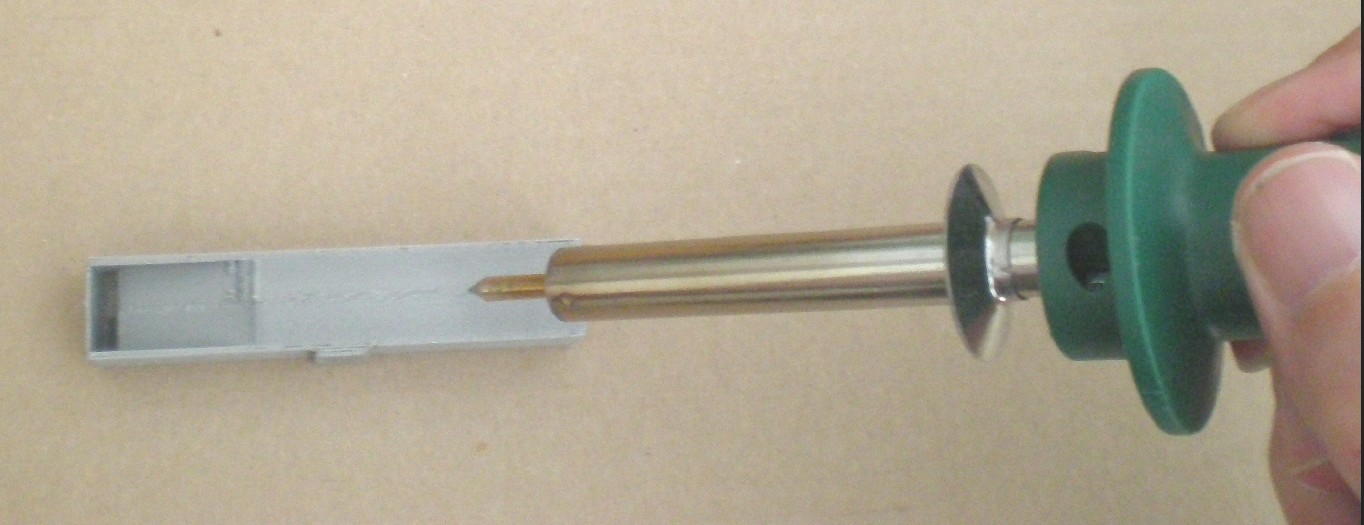

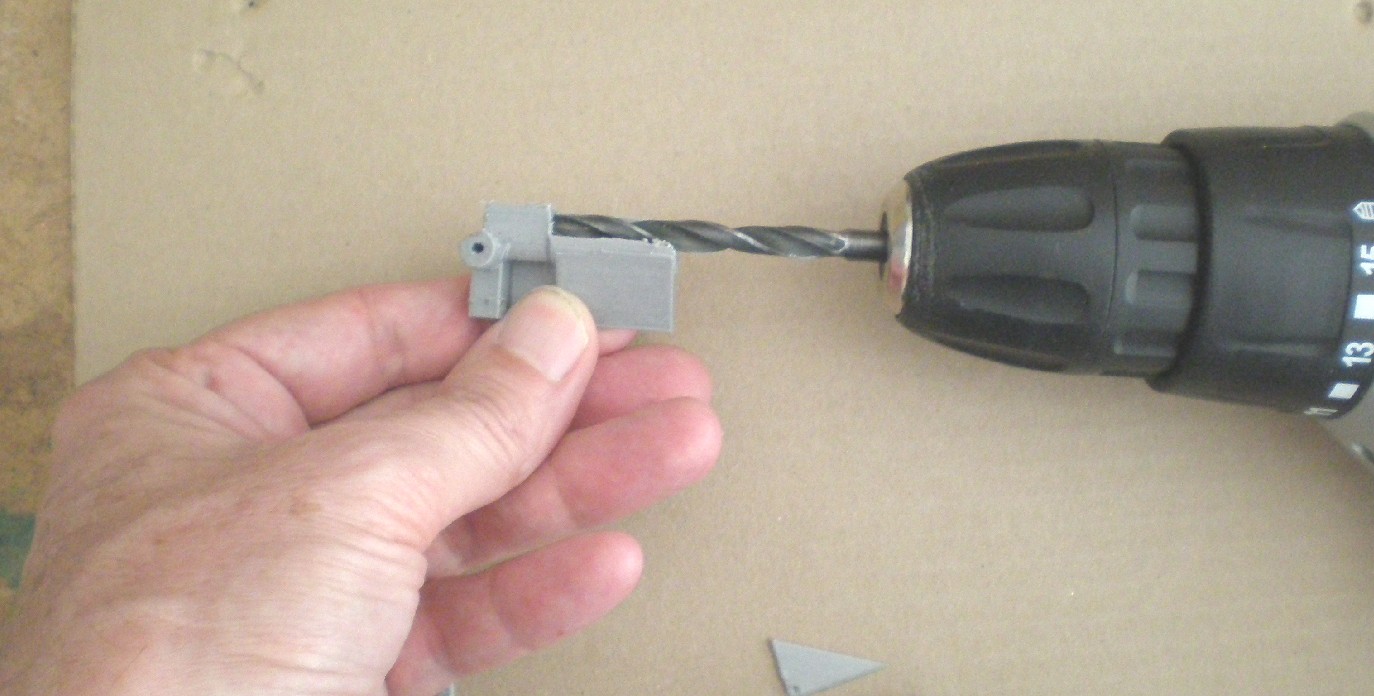

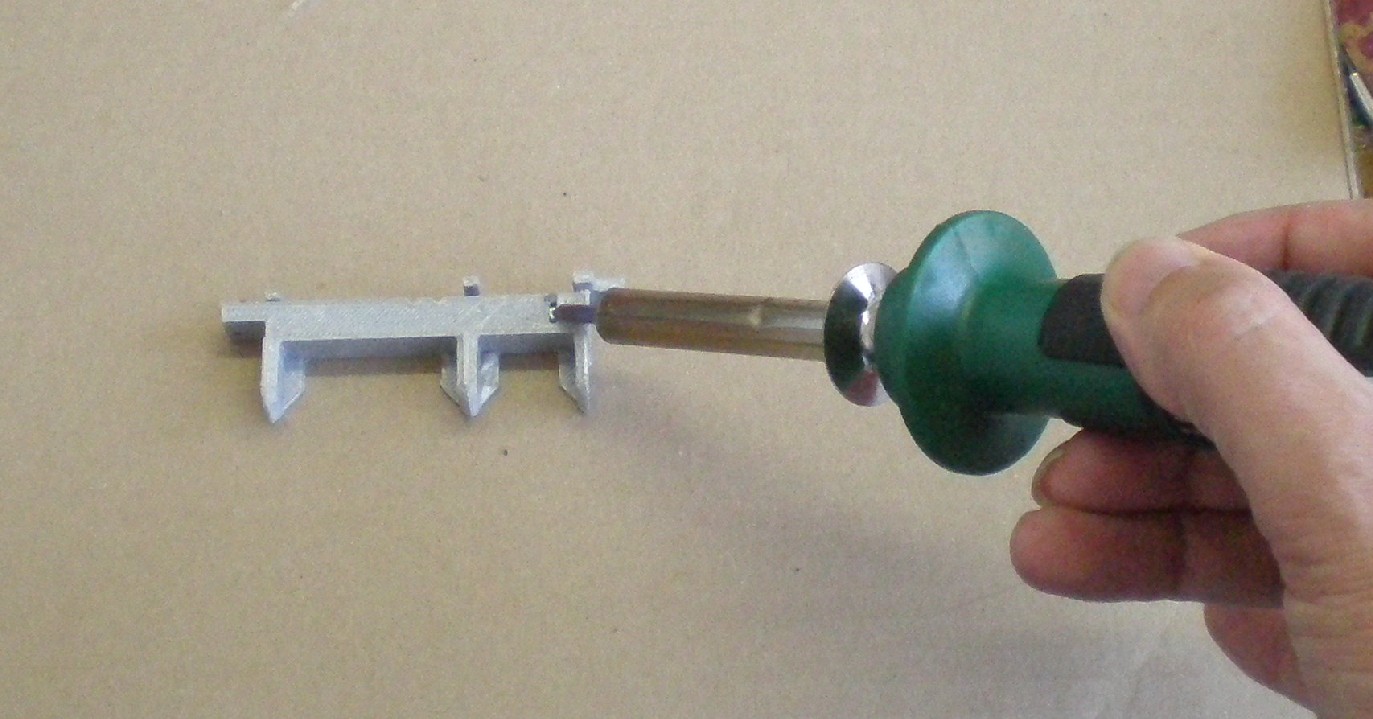

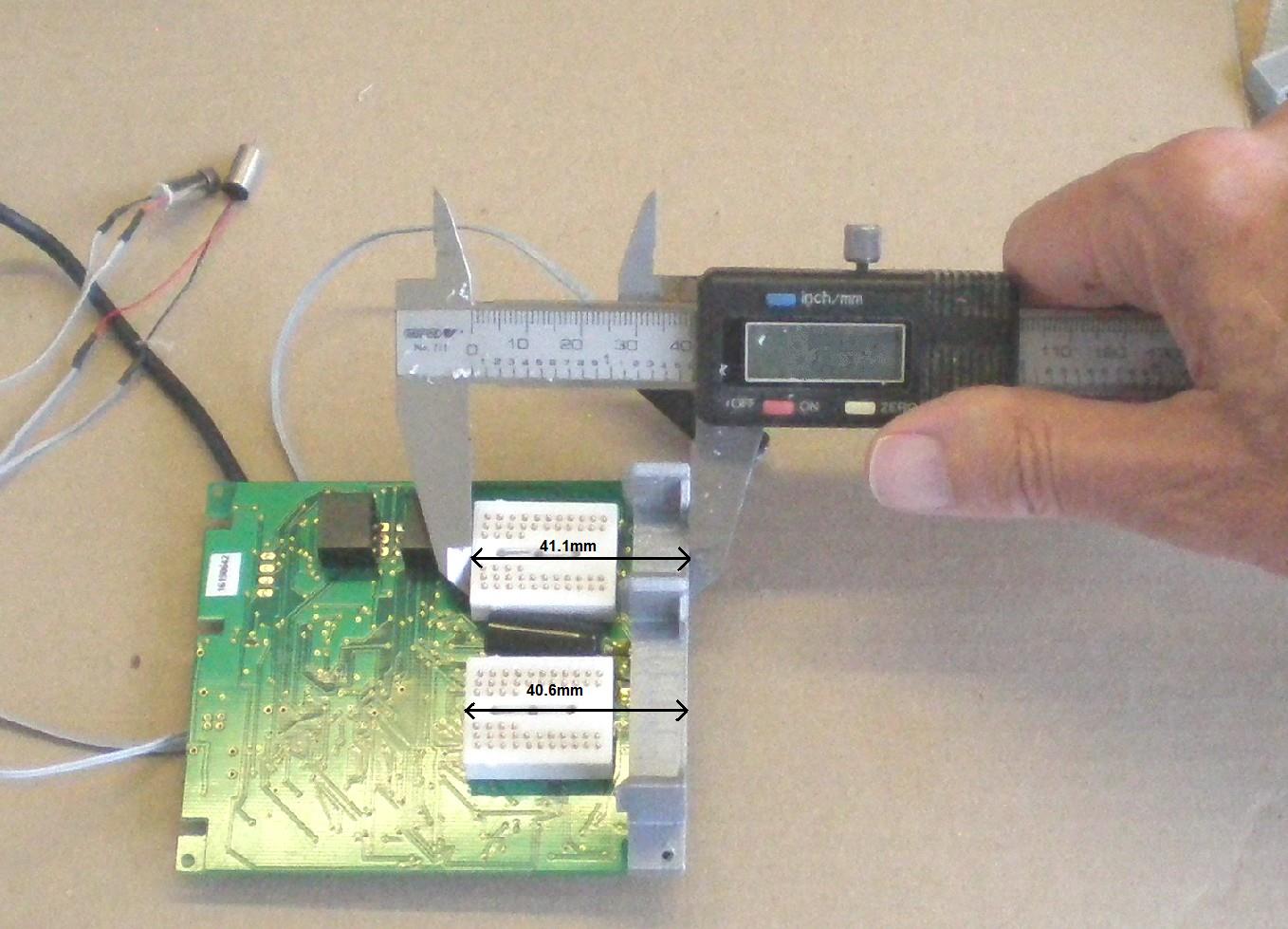

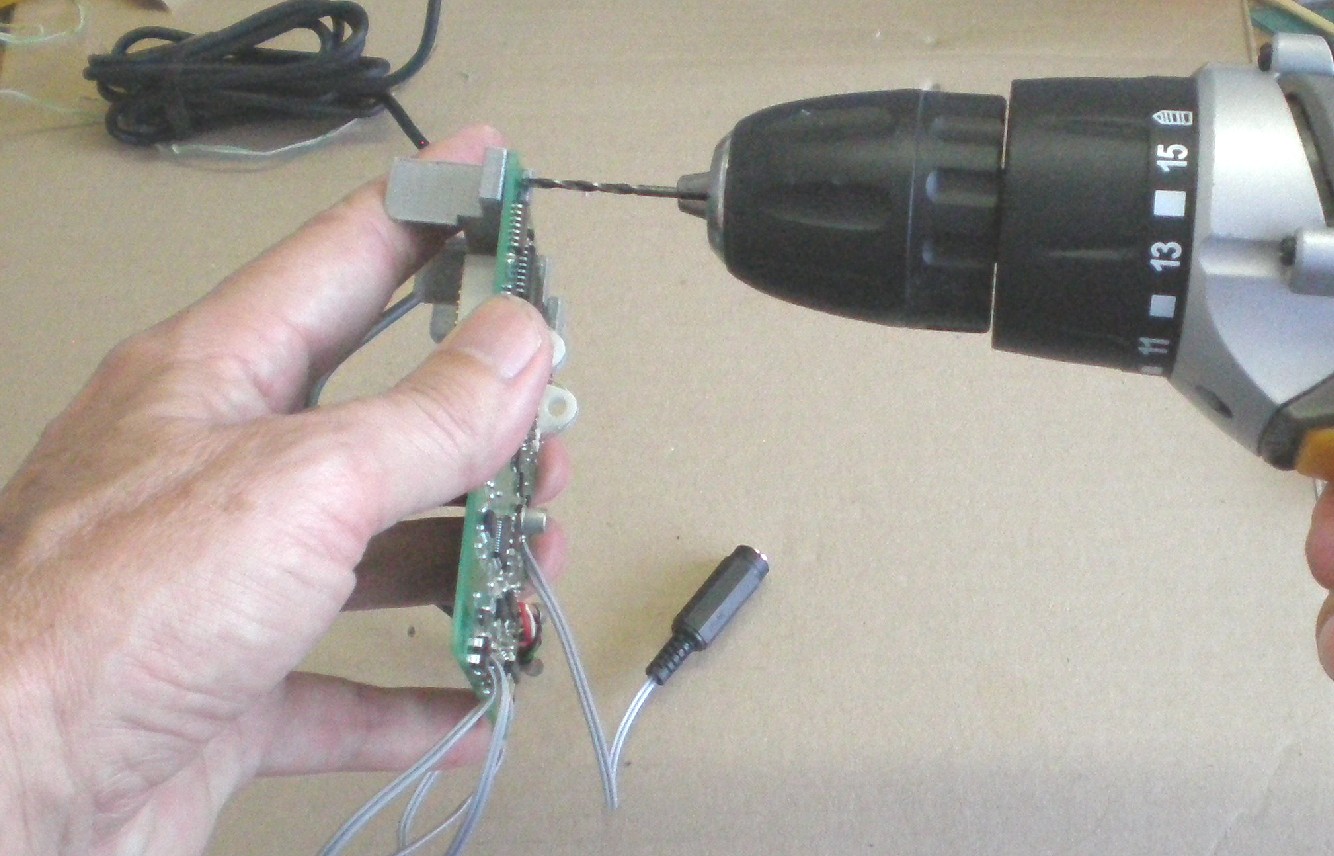

This hole needs to be 6mm . When you use a drill to enlarge it is easiest when you let the drill run in reverse.

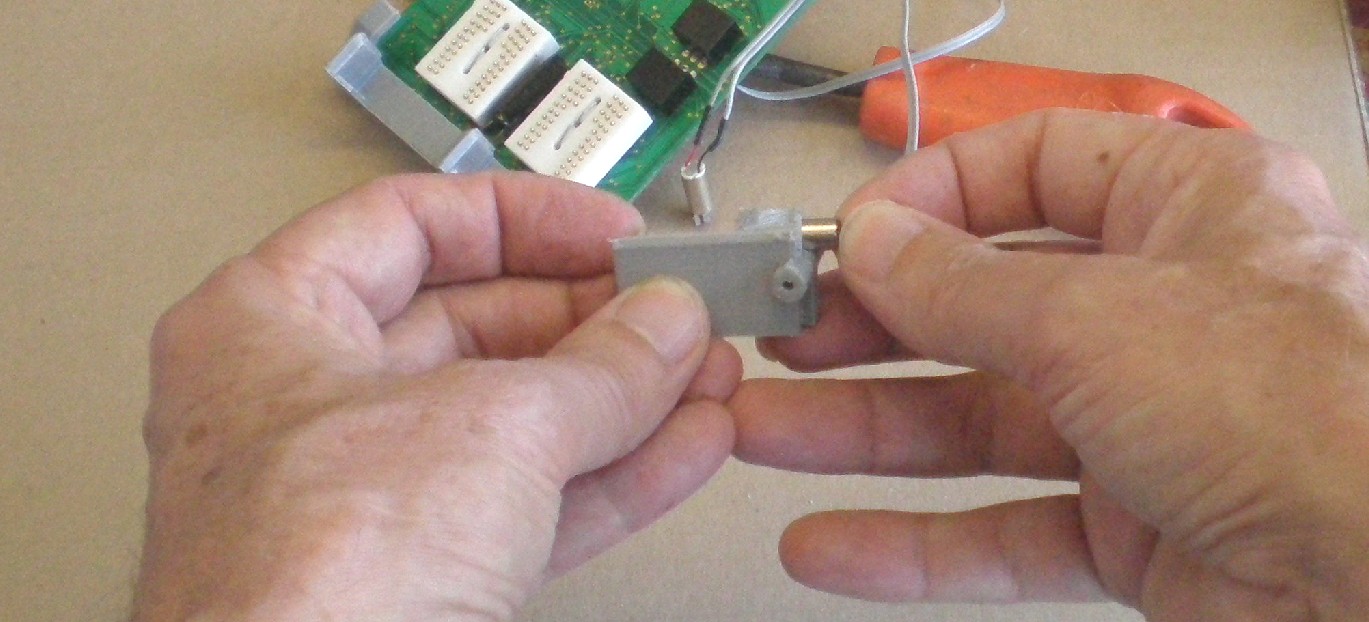

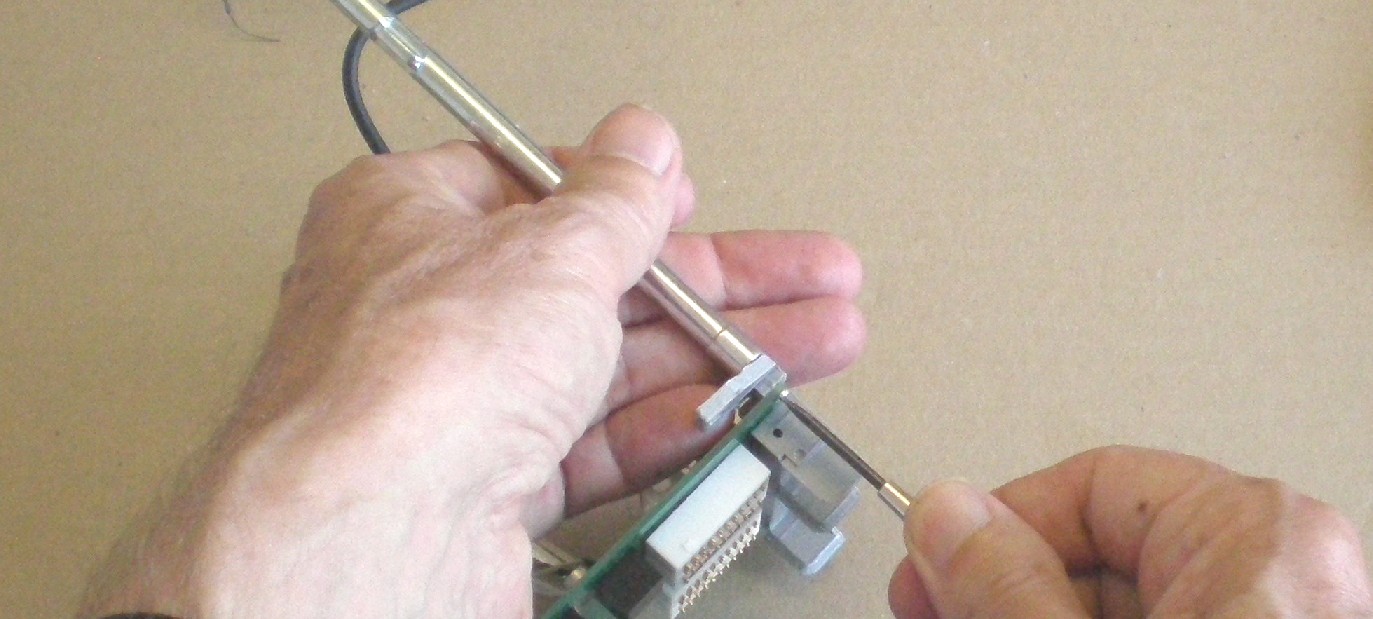

Check if you can slide in the roller motor.

If it does not fit you need to enlarge a little more with a file.

This hole needs to be enlarged to 2.5mm.

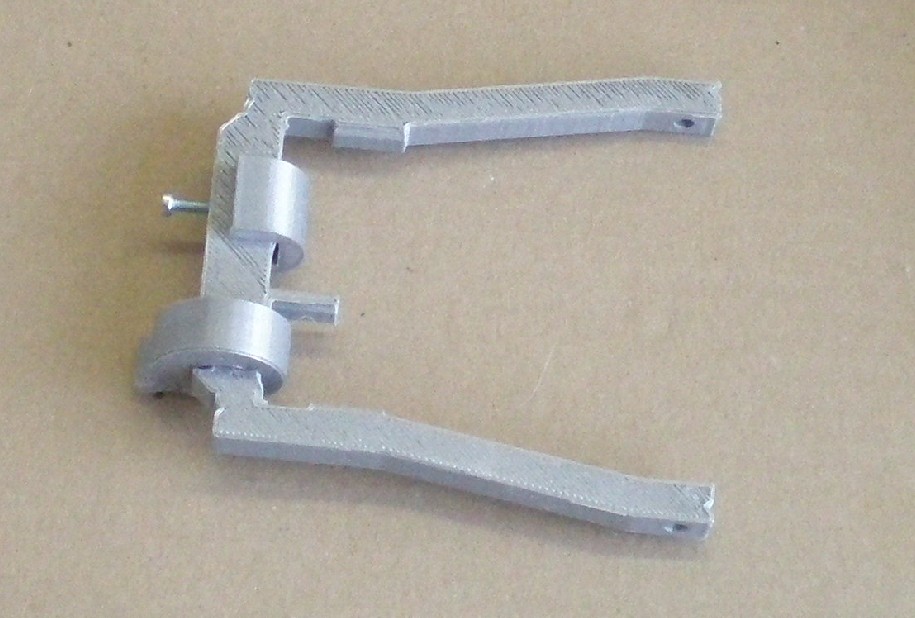

These are parts of the cartridge clamp.

There is an updated design of this clamp. You can download the stl file here

Glue in the small part on the outside.

Put in a M3 screw and a nut.

Put this part over the clamp.

Press a M2 nut into this part with a soldering iron.

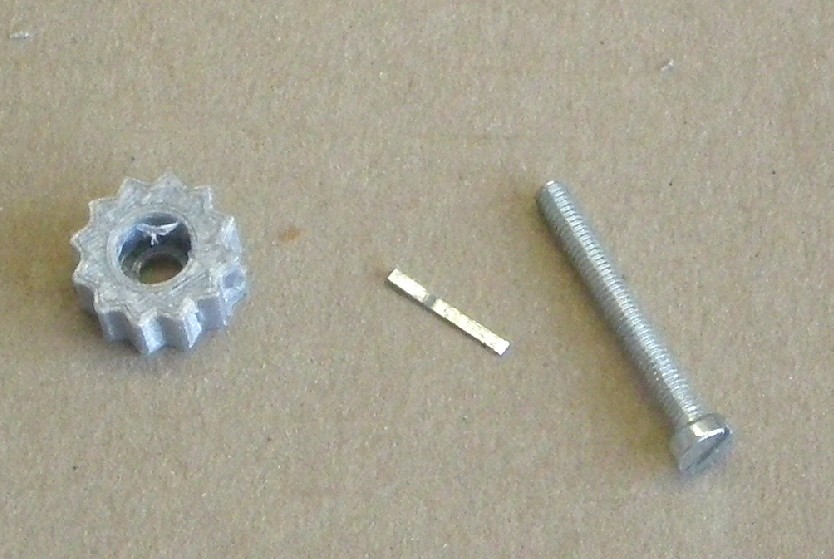

These are a knob a piece of a staple and a m3 bolt.

Use the staple to secure the knob.

Fix it all with glue.

Press and secure an m2 nut in this wheel with a soldering iron.

Glue this part on the powder sprinkler.

Before you place this part check if the inkjet cartridges fit in.

It is very important that this part is on the right position on the pcb. It is best to secure this part with hotmelt first.

Drill the holes (in reverse) after you secured the part on the right position.

Fix this part together wit part 13 with M2 screw and bolt.

Fix the other side together with part 14

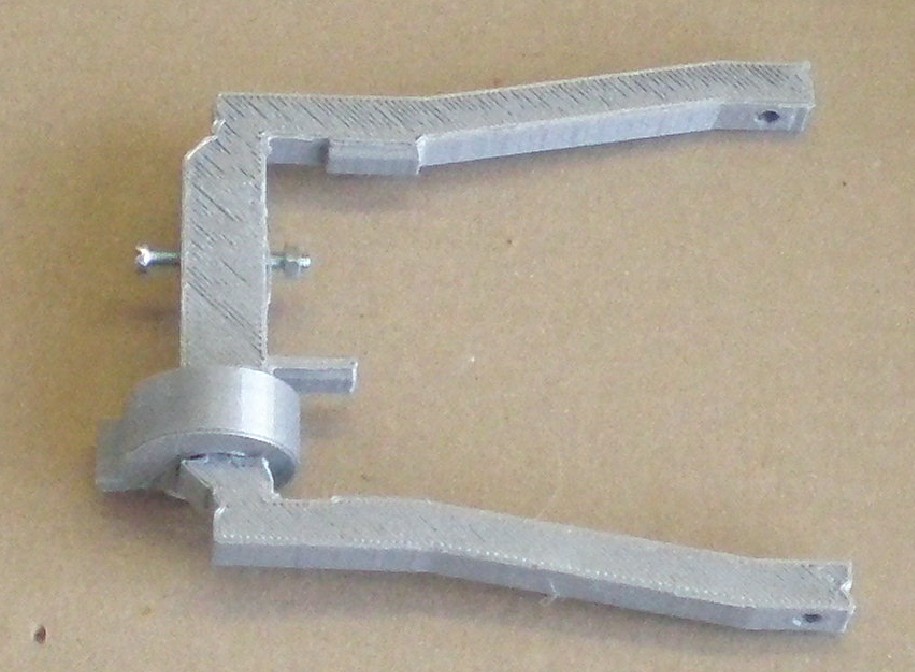

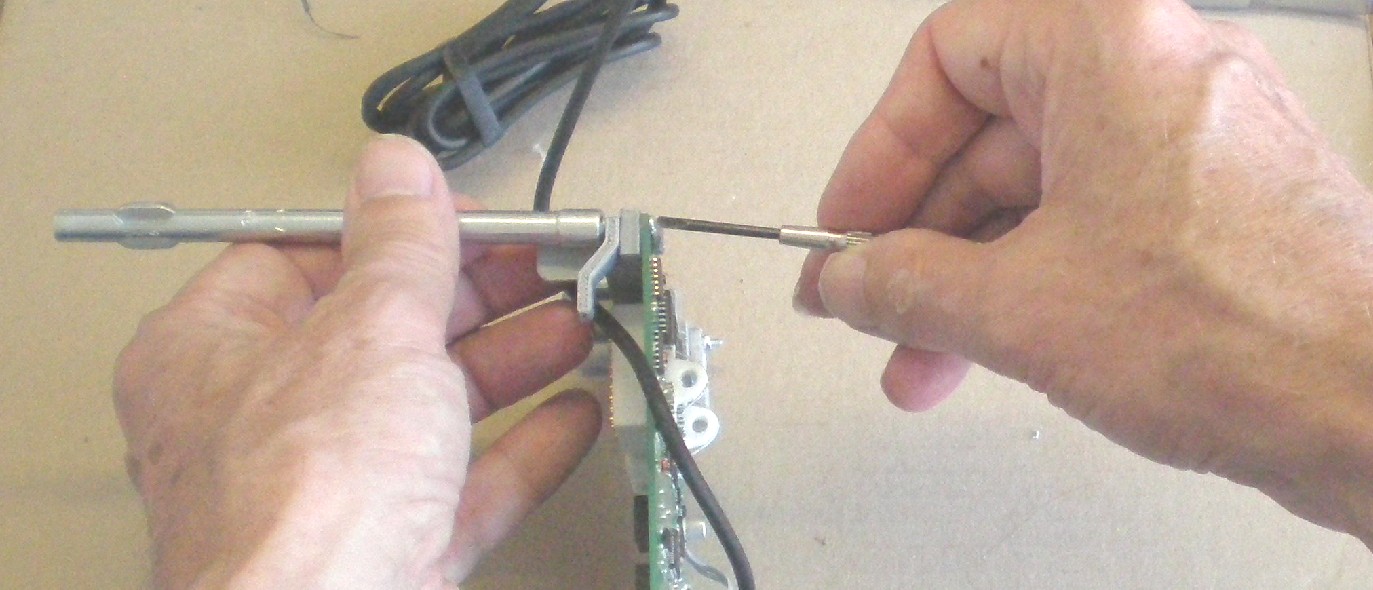

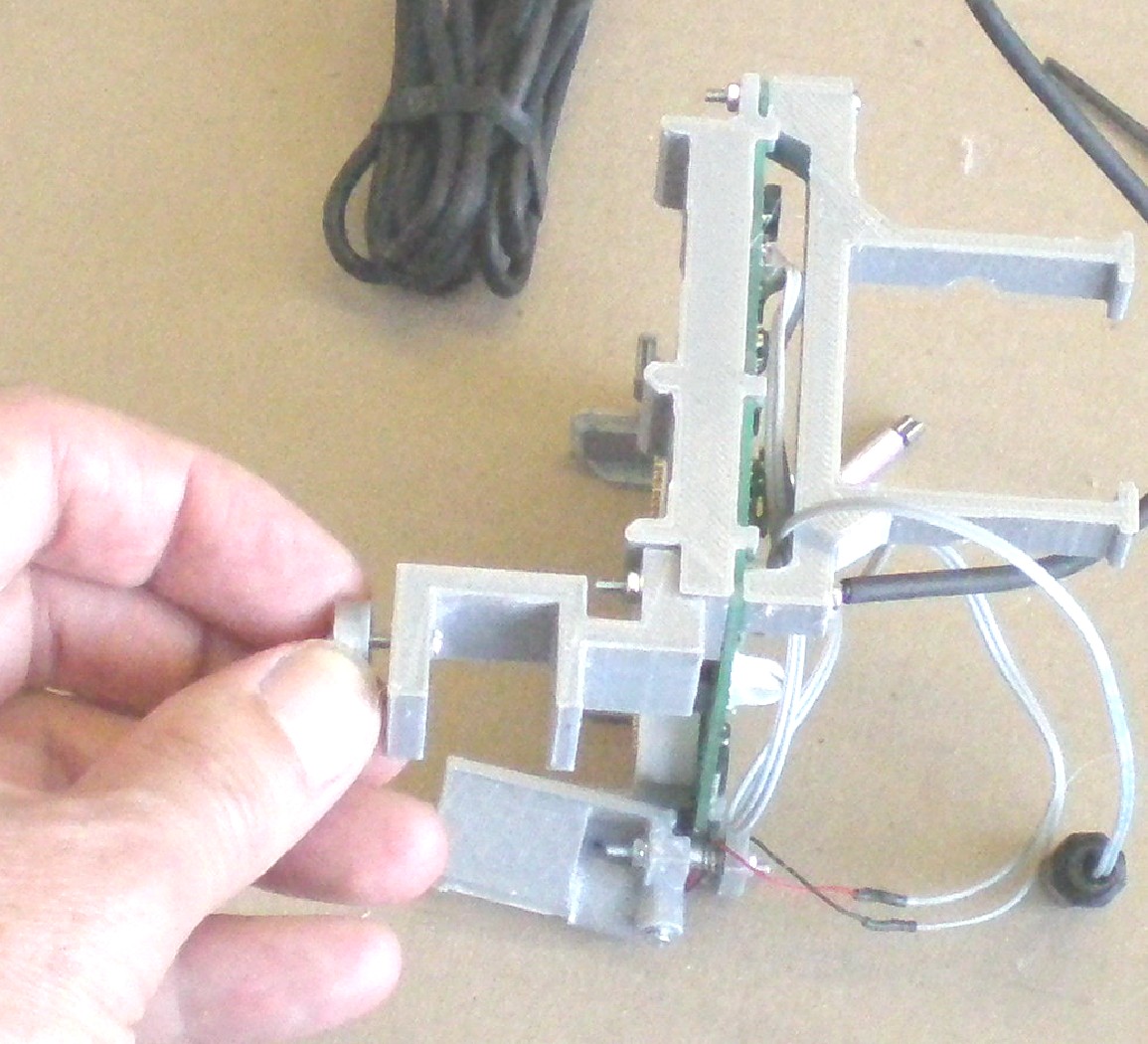

Slide the roller motor in.

Attach the roller unit with a M2 screw.

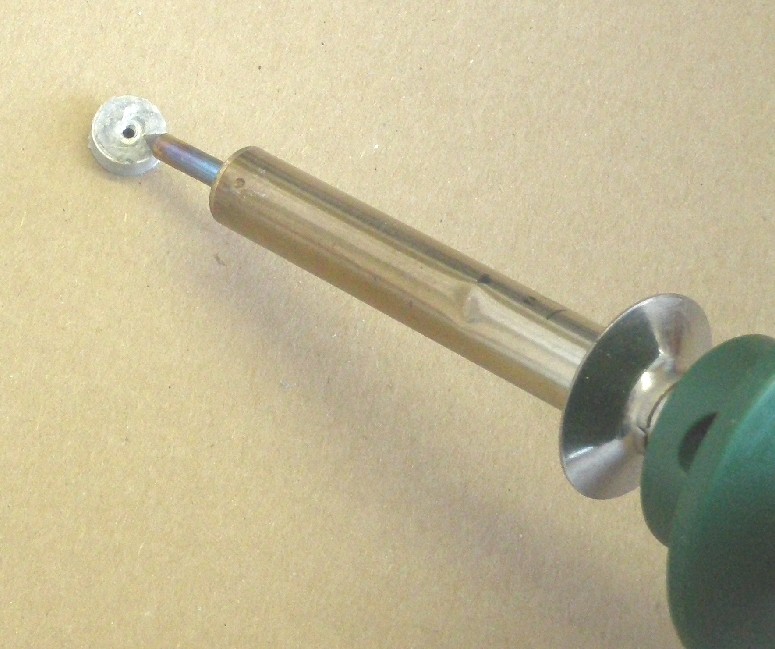

Slide the teflon cylinder on the motor axis. Check if it can turn without obstruction.

Place a metal (ballpoint) spring between these two part.

Put in a M2 screw.

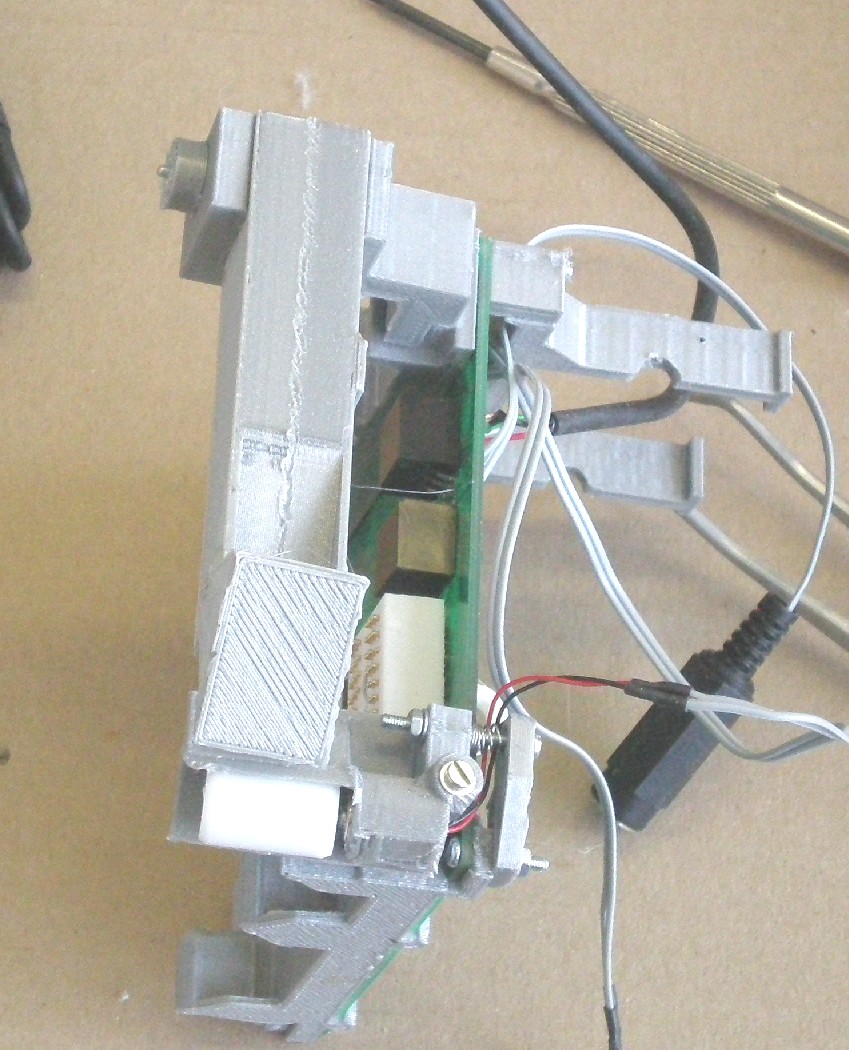

Screw these two parts on the pcb.

On the front side add this part.

Place the screw and the wheel.

Slide in the powder sprinkler.

Glue the vibration motor to the powder sprinkler.

Place the screw with knob into this part.

Slide int the 4mm rod to bring it all together.

The complete set.

The added part is to secure it on the UM2 extruder.

The Ultimaker sync cable.

This where the sync cable must be connected to the ultimaker board.

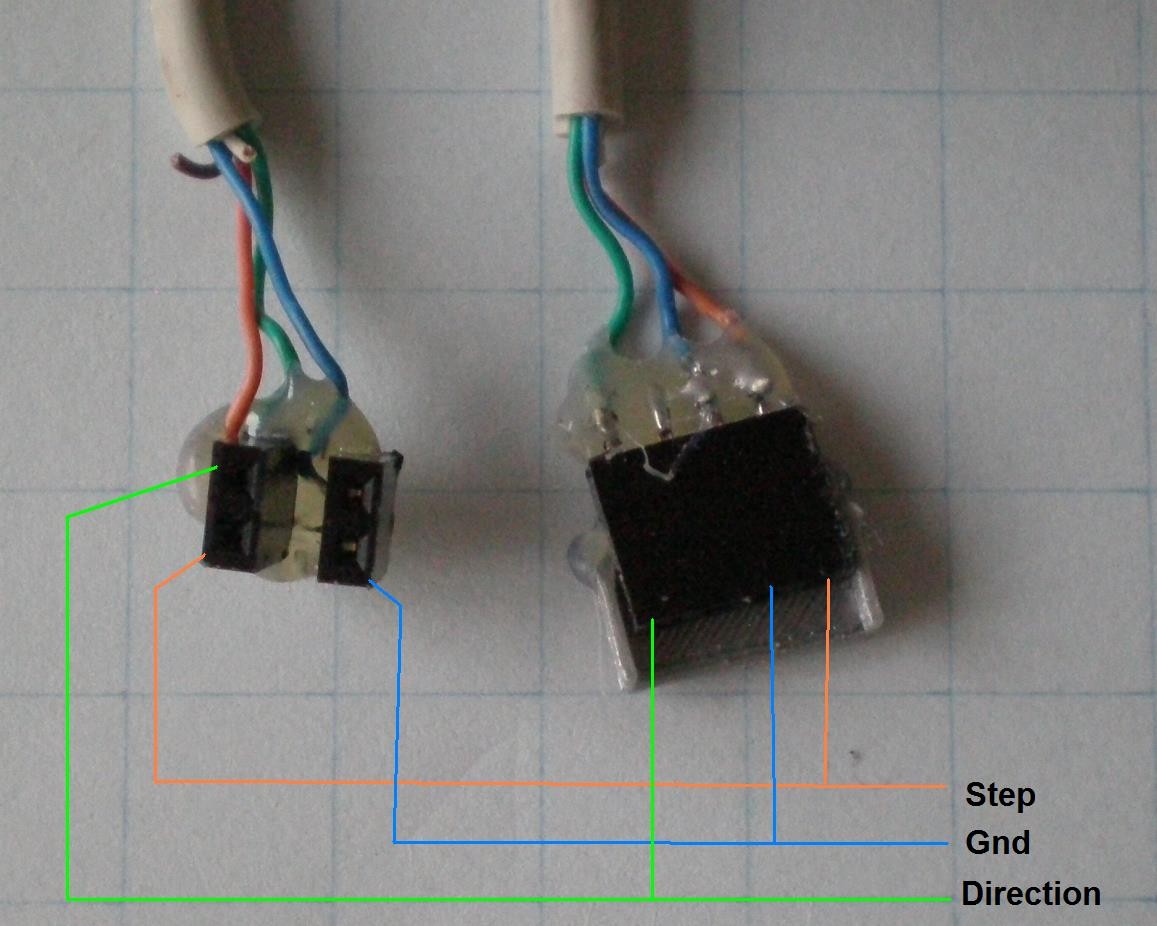

This is how you connect the colorpod to the y stepper driver on a ramps board.